Quality Control & Assurance Standards

At Rovimech Automation Pvt. Ltd., quality is not just a process — it is a culture we follow in every stage of machine building, system integration, and electrical panel development. Our quality standards ensure that every solution we deliver is reliable, safe and performance driven.

- Quality Control & Assurance Standards

- 1. Scope & Objectives

- 2. Quality Policy & Rules

- 3. Roles & Responsibilities

- 4. Quality Process Flow

- 5. Inward Quality Control (Incoming Inspection)

- 6. In-Process Quality Control

- 7. Outward Quality Control (Final Inspection)

- 8. Factory Acceptance Test (FAT)

- 9. Non-Conformance & Corrective Action

- 10. Documentation & Traceability

1. Scope & Objectives

Our quality control system applies to: –

QUALITY SCOPE: –

- Special Purpose Machines (SPM)

- Vision inspection systems

- Robotics and automation solutions

- Electrical control panels

- QUALITY OBJECTIVES: –

- Ensure all incoming materials meet specifications.

- Monitor and control every stage of manufacturing.

- Guarantee that every machine and panel passes performance and safety checks.

- Maintain full documentation and traceability for customer assurance.

2. Quality Policy & Rules

We are committed to delivering automation solutions that meet or exceed customer requirements.

Our Quality Rules: –

- All incoming materials are inspected within 48 hours of receipt.

- Defective or non-conforming parts are immediately quarantined.

- No machine or panel is dispatched without passing a complete final inspection and Factory Acceptance Test (FAT).

- All measuring and testing instruments are calibrated and certified.

- Critical components are tracked by serial or batch number for traceability.

3. Roles & Responsibilities

- Quality Manager: Defines standards, verifies reports, and leads corrective actions.

- Receiving Inspector: Performs inward inspection and prepares Material Acceptance Reports (MAR).

- Production Supervisor: Ensures in-process checks and compliance with work instructions.

- Electrical Lead / Panel Builder: Performs wiring inspections, continuity, and insulation checks.

- Test Engineer: Conducts functional and FAT testing.

- Stores & Logistics: Ensures proper labeling, storage, and packaging for dispatch.

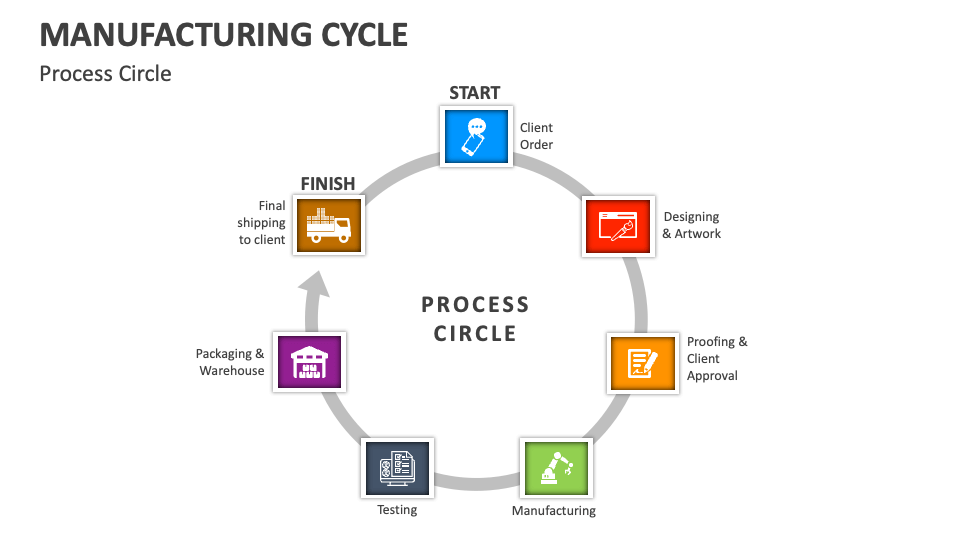

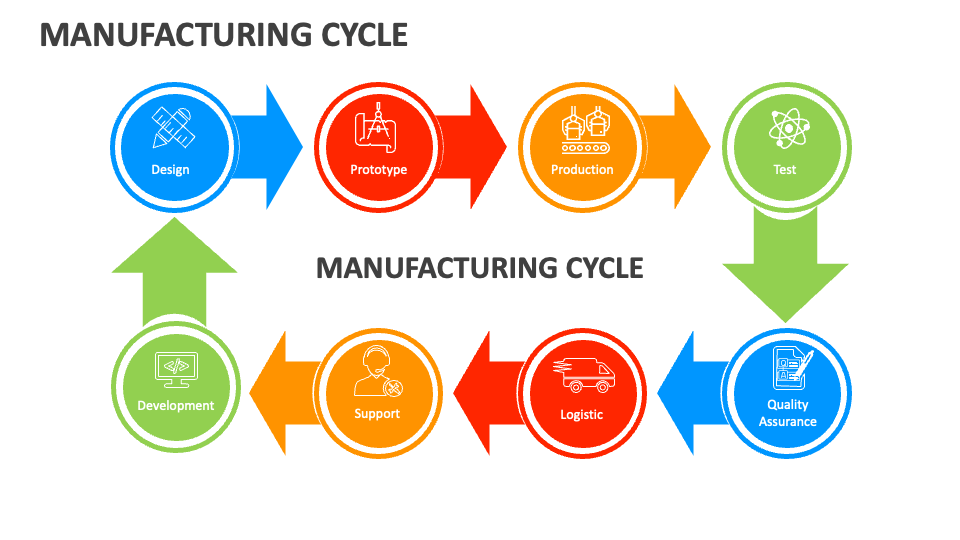

4. Quality Process Flow

- Supplier approval and purchase order verification

- Receiving & inward inspection of materials

- Storage with identification and traceability

- Mechanical assembly & in-process inspection

- Electrical panel build & wiring checks

- System integration and functional testing

- Final inspection & Factory Acceptance Test (FAT)

- Packing, labeling, and outward inspection

- Customer Site Acceptance Test (SAT)

- Feedback collection and continuous improvement

5. Inward Quality Control (Incoming Inspection)

Every received item undergoes checks for:

- Part numbers, quantity, and supplier documentation

- Visual inspection for damages or corrosion

- Dimensional checks using calibrated tools

- Electrical ratings and certifications (CE/UL)

- Calibration certificates for critical instruments

Material Acceptance Report (MAR) includes:

- Supplier details & PO number

- Inspection date and inspector name

- Test results and measurements

- Acceptance / Rejection status

- NCR number (if non-conforming)

6. In-Process Quality Control

Mechanical Assembly Checks:

- Fit and alignment of parts

- Torque verification for fasteners

- Welding, surface finish, and protective coating

- Correct lubrication

Electrical Panel Checks:

- Wiring as per schematic with proper tagging

- Grounding and continuity checks

- Insulation resistance & HiPot testing

- PLC I/O verification and sensor connections

Software & Configuration Control:

- Version tracking for PLC/HMI/vision programs

- Change notes and re-testing for software updates

7. Outward Quality Control (Final Inspection)

Before dispatch, every system is inspected for:

- Closure of all inward and in-process inspection reports

- Torque logs and alignment checks

- Electrical test records (continuity, insulation, HiPot)

- FAT execution covering safety, performance, and functionality

- Documentation package (drawings, wiring diagrams, PLC programs, manuals)

- Proper packaging with safety indicators (anti-static, shock, tilt)

8. Factory Acceptance Test (FAT)

The FAT ensures machines meet design and contractual requirements. It includes:

- Pre-test inspection and power-up sequence

- Functional cycle testing

- Safety device validation (E-stops, guards, interlocks)

- Throughput and performance checks

- Data communication and logging verification

- Customer witness sign-off (if applicable)

9. Non-Conformance & Corrective Action

If a defect is found:

- An NCR (Non-Conformance Report) is issued with details and photos.

- The part/machine is quarantined.

- Containment and immediate corrective action are taken.

- Root Cause Analysis (RCA) is performed.

- Corrective and Preventive Action (CAPA) plan is implemented.

- Quality team verifies and closes the NCR.

10. Documentation & Traceability

Every project maintains inspection records, calibration certificates, test reports, and checklists.

- All reports are stored digitally for a minimum of 3 years.

- Each critical component and software version is traceable to the project/job number.